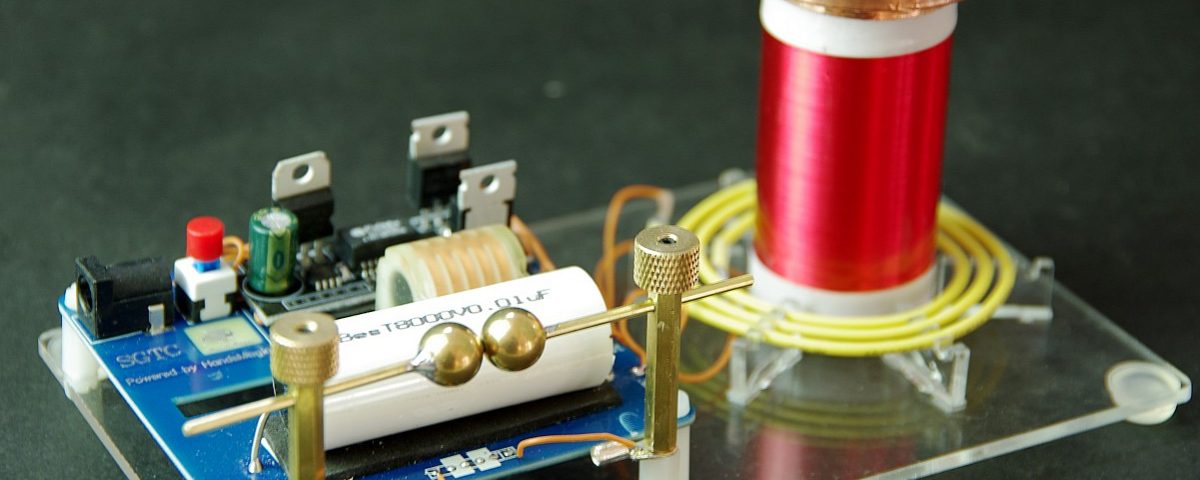

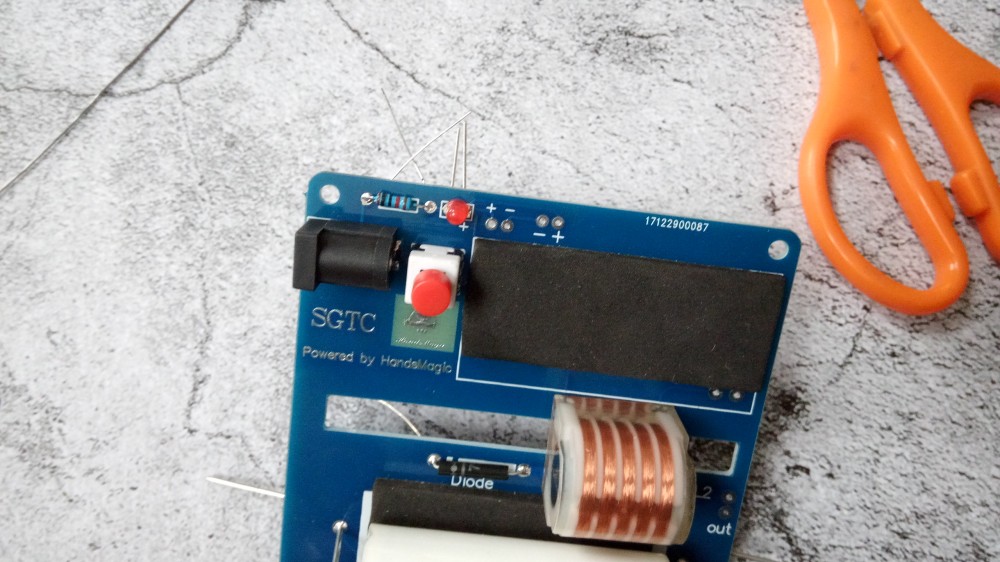

mini ball-gap spark tesla coil SGTC

tiny stirling engine 01

12月 5, 2018Solarbotic simple1

3月 17, 2019

In the DIY process, if you have any questions that you don’t understand, please send an email to our email address(bluefox911@163.com), the title says SGTC, we will reply you in the first time after seeing it.

This is a mini spark gap tesla coil(SGTC),it is small but full funtion.The most important thing is that it can touch and don’t worry about the electric shock injury.The original intention that we design this decive,plz reference The following article

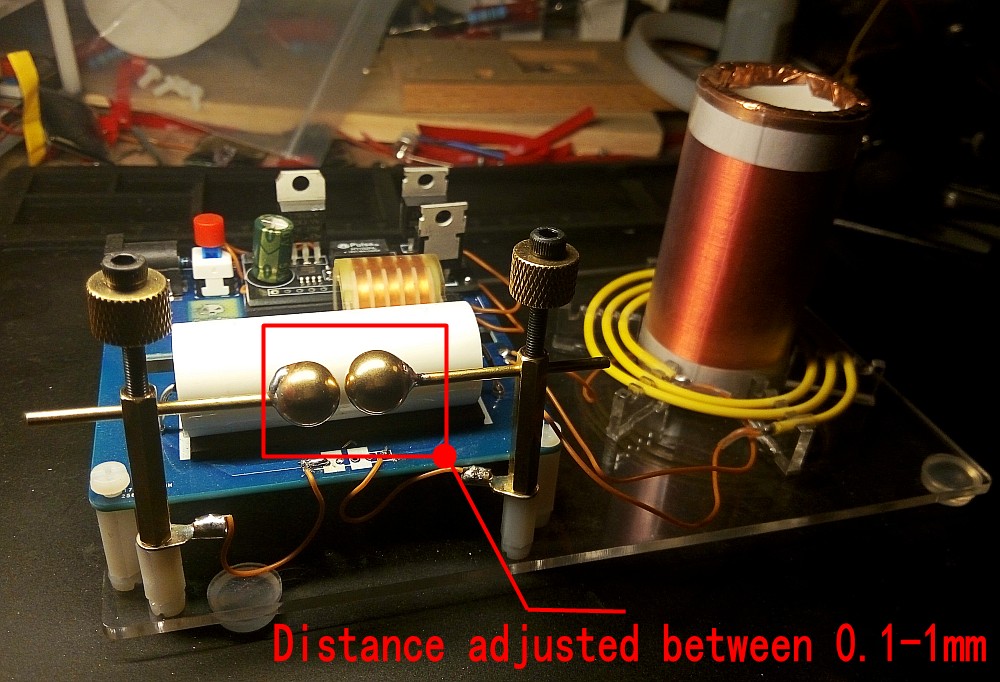

First briefly introduce this Tesla coil project:this is the third mini SGTC Project,It is basically the same as the previous three Project, except the part of the spark gap, we use the ball gap

The ball gap can be adjusted, the basic range is between 0.1-1mm, different gaps will lead to different discharge frequencies and charging voltage of the capacitor, so the discharge effect is different, you will feel the fun of trying………..

OK,let us start making it

Step1

Foam is buffered at the bottom

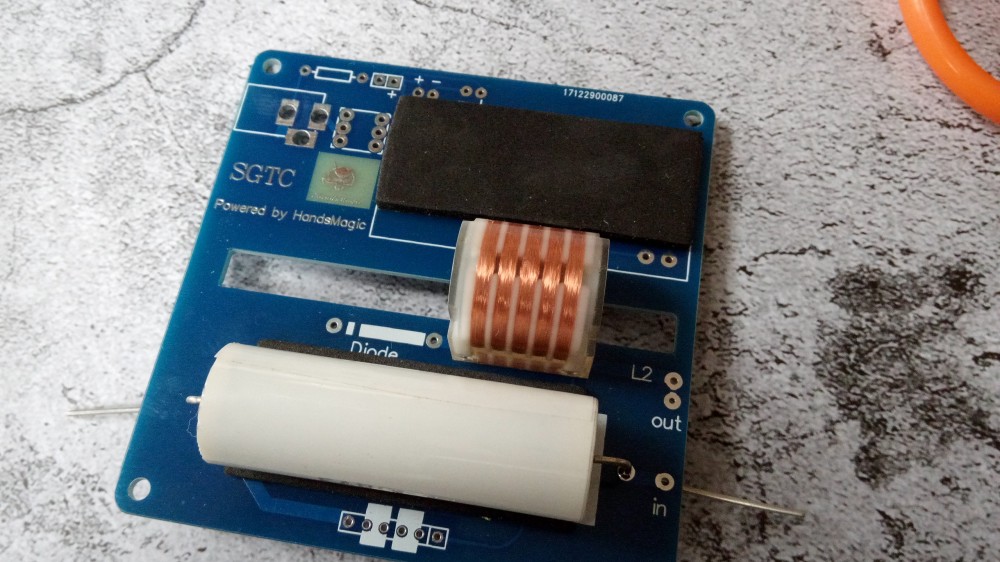

step2

The transformer coil needs to be installed according to the picture, and the rough copper wire is the primary position.

Please look at the annotation on the picture

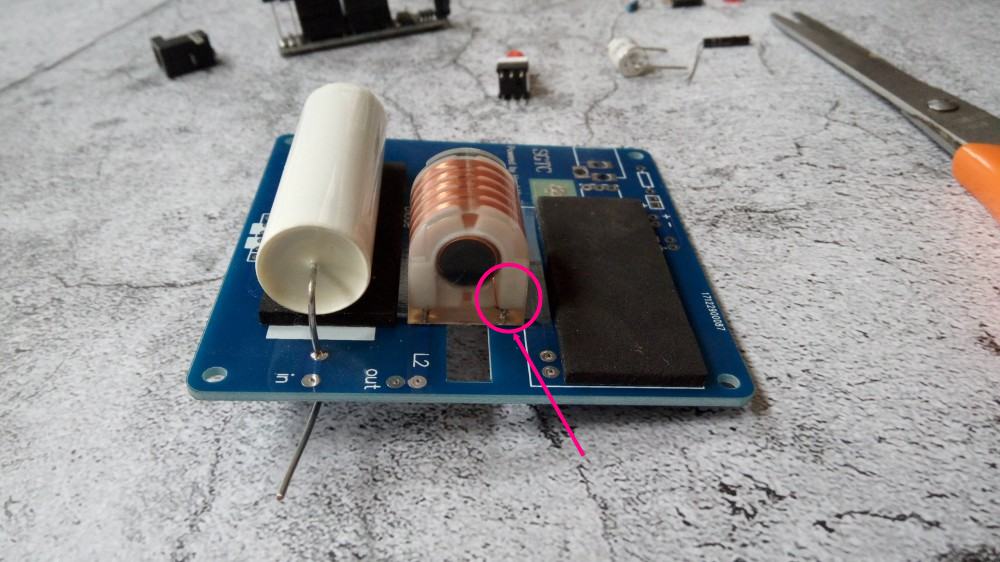

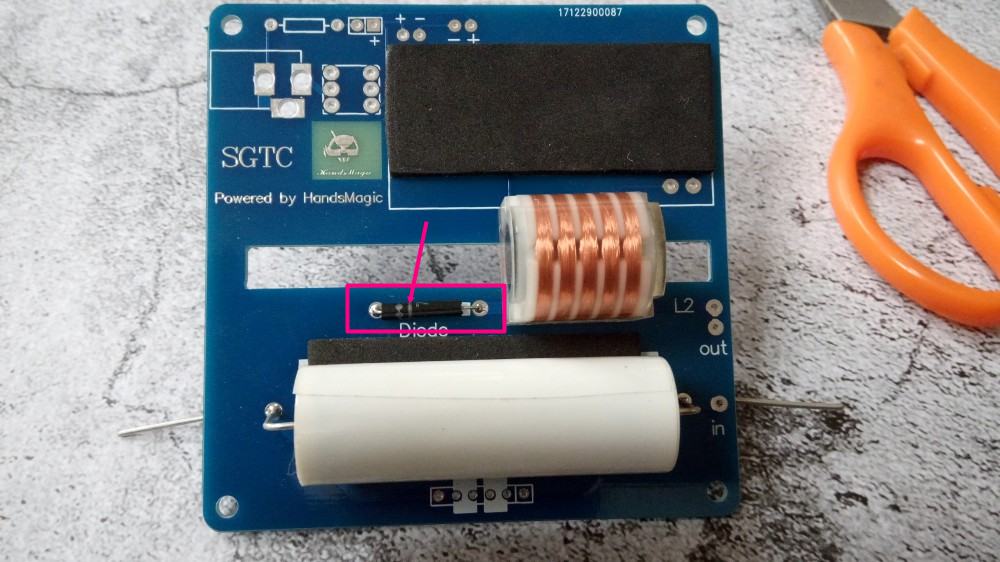

step3

High voltage diode

step4

Power indicator lamp,led long foot is +

step5

Power socket and switch

step8

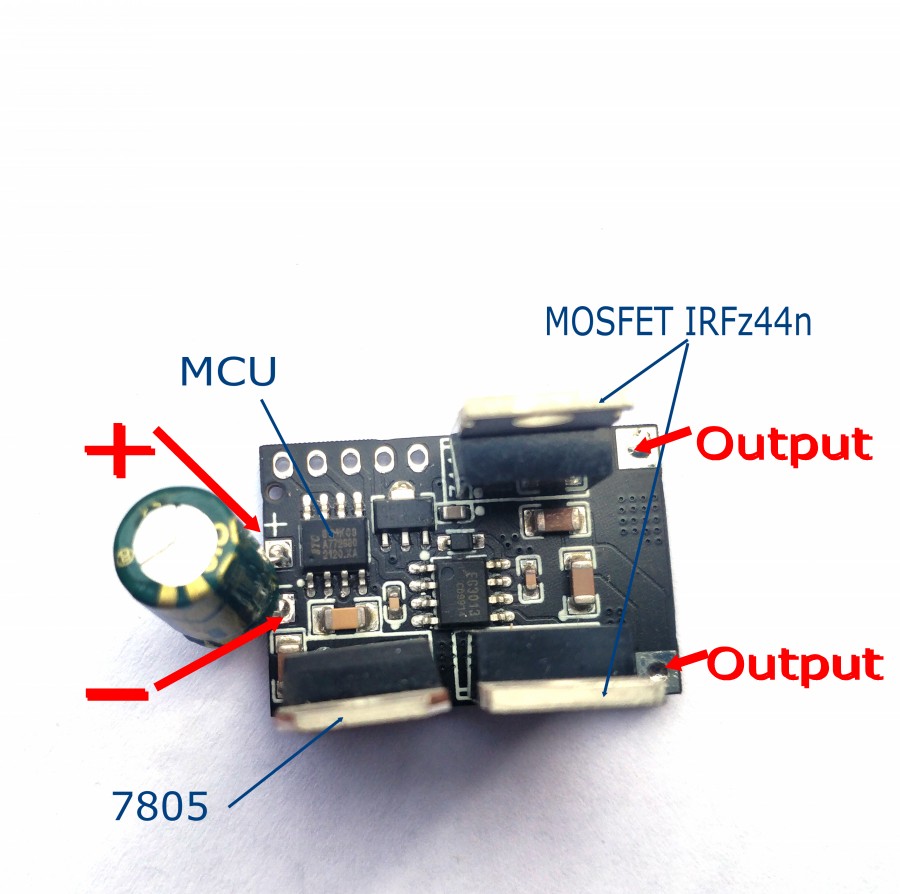

High voltage signal generator(Third generation board)

solder wire

soldering to the right place marked in picture below,on the board you can see “+” and “-”

There are “+” and “-” on the board, and we must carefully weld, “+”to “+”

ok,the board finished

step9

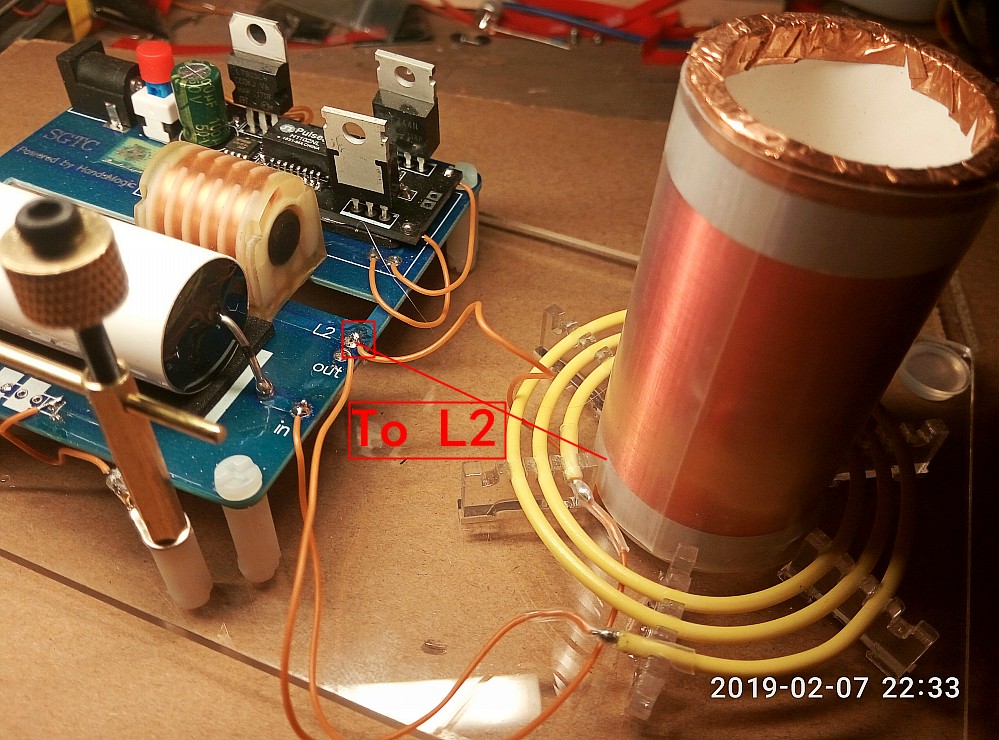

now need connect the Primary coil and secondary coil to this board

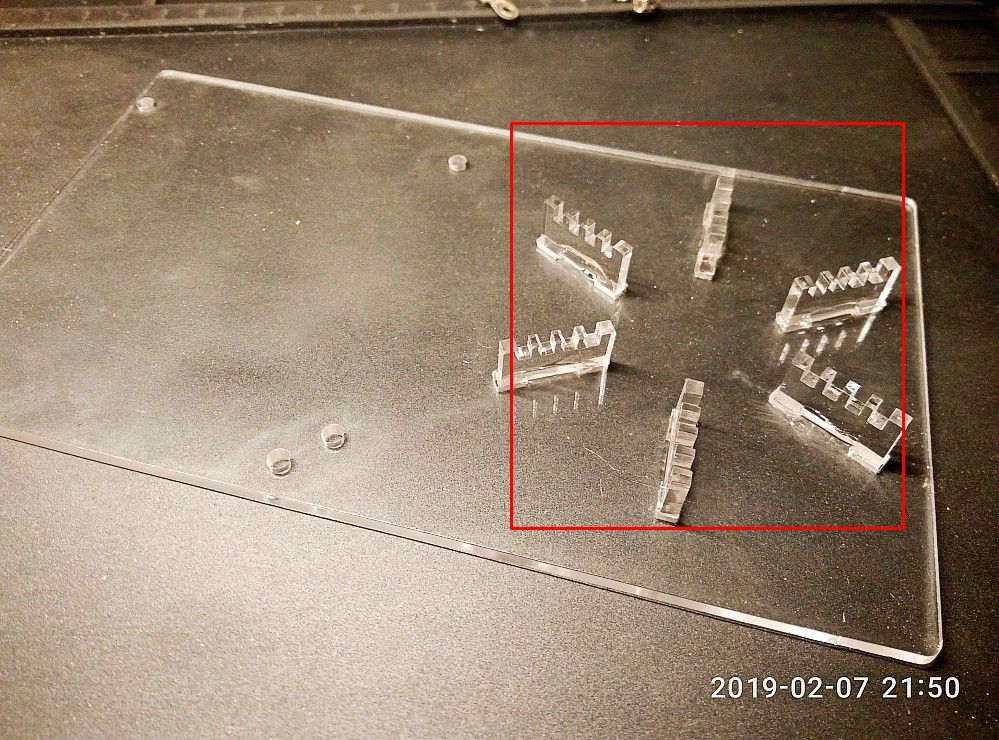

first glue the bottom shell

In order to look good, we use UV curing glue, transparent

The perfectionist can be like us, but if you do not mind

Then just like you,Any glue is all right.

(Acrylic board back)3 silicone pads stuck in the corner

Another need to reserve space for the nut, so don’t stick to the corner

Assemble the board

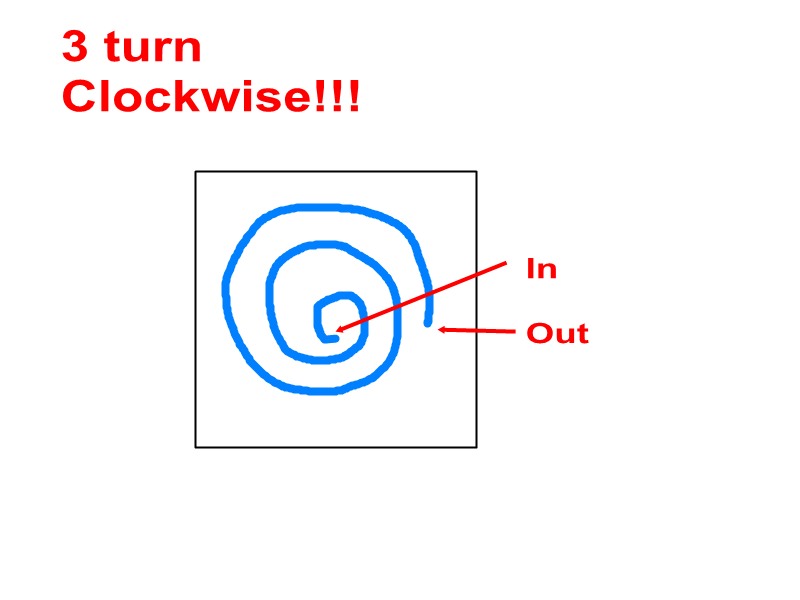

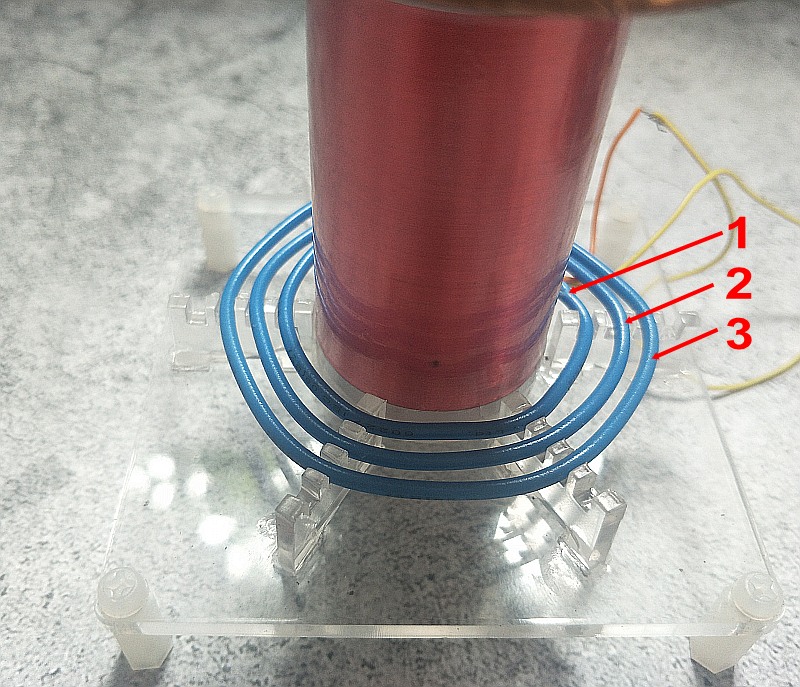

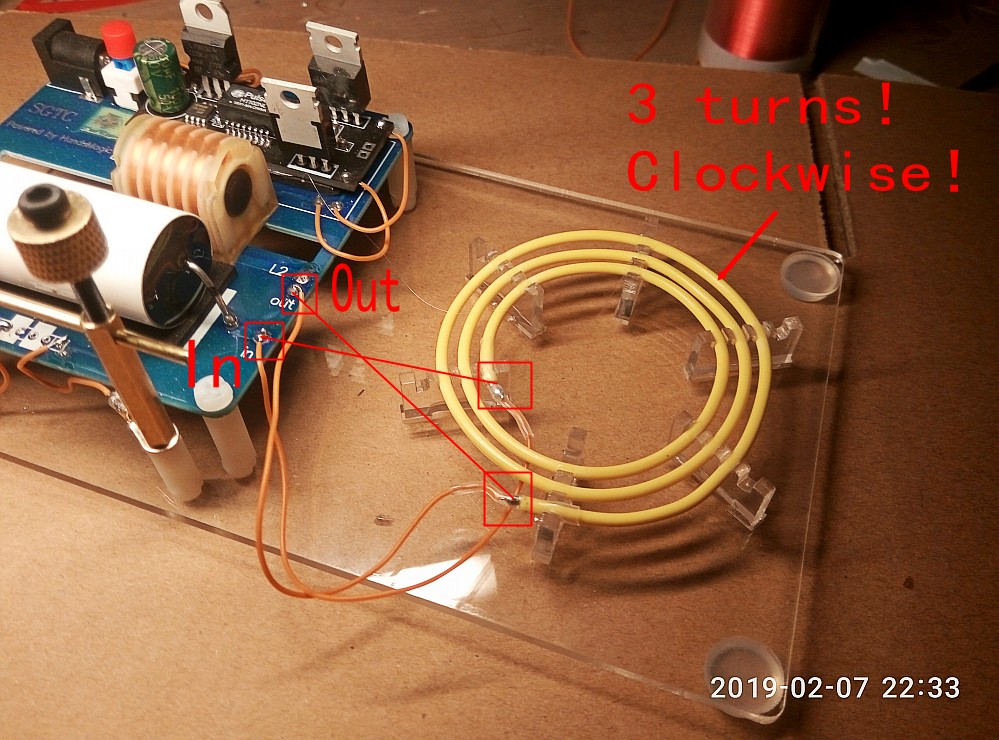

The primary coil winds three turns(Although the bottom is reserved for 4 turns, but please winds only 3 turns,and must Clockwise)

Now solder the “IN” “Out” “L2”

The soldering place is best to do insulation treatment,

Prevent discharge(Cover exposed wires with tape)

The wire of the secondary coil is soldered to “L2″

In fact,” L2″ and ” Out” is connected…………

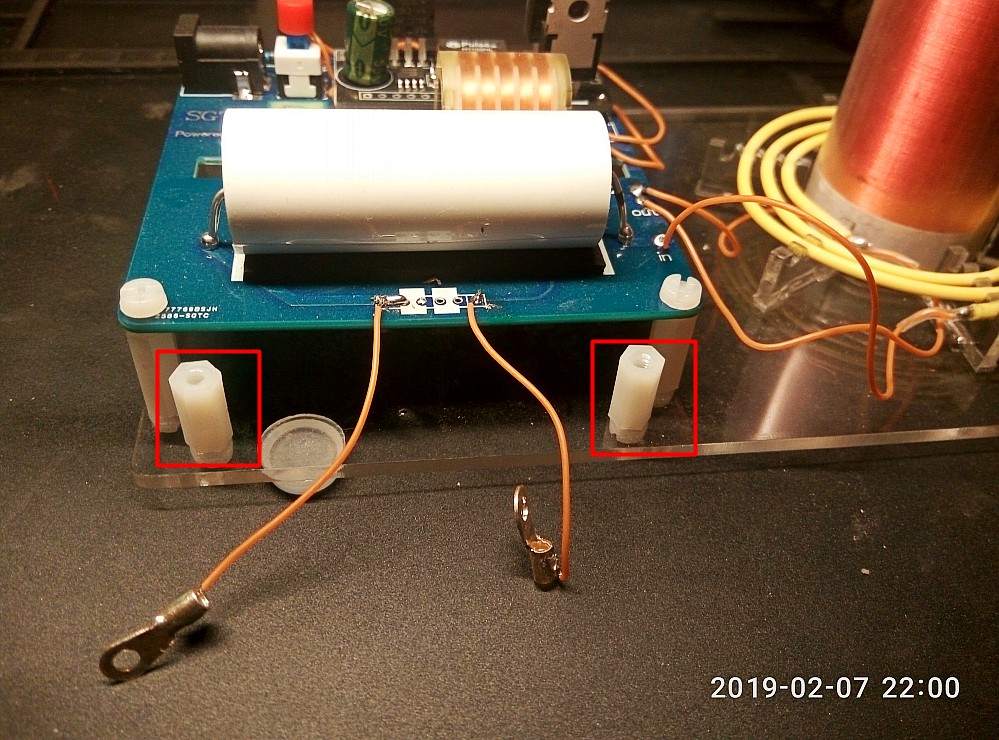

install the Nylon nut ………..

Copper column,make sure the hole on the Copper column is like picture

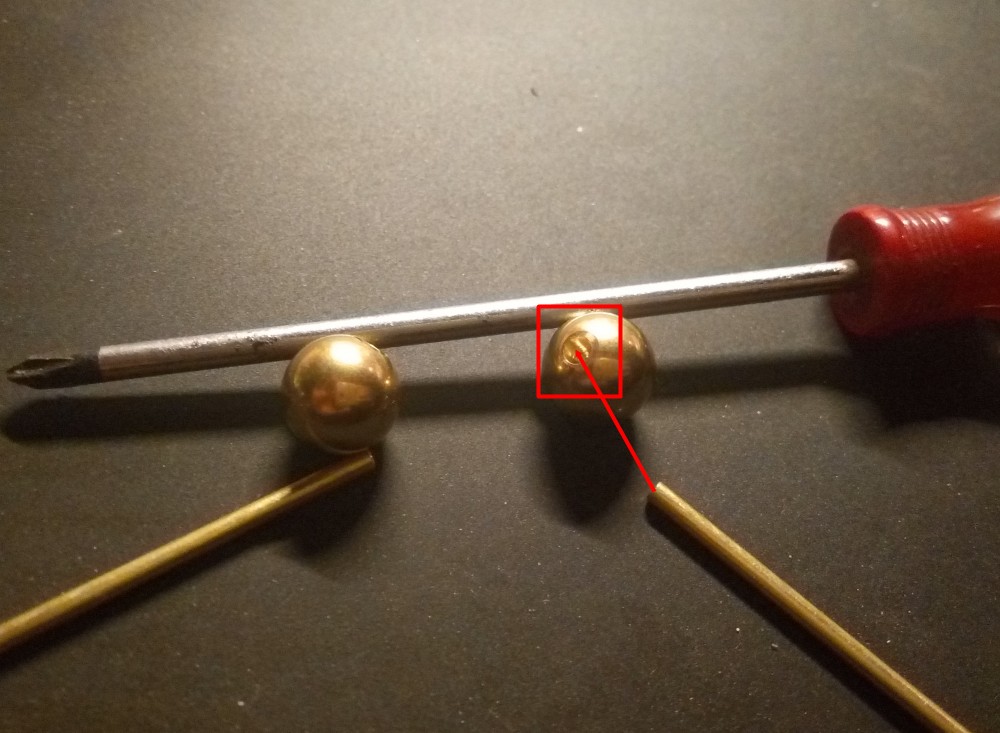

the Copper ball has hole,you need solder the Copper stick on the hole….

Adjust the distance of the copper ball, the interval should be less than 1mm, otherwise the voltage can not work through the air, it can not work, can be adjusted in the range of 0.1-1mm, can get different discharge effects

Determine the distance and lock with the nut………..

Ok,finished all the assemble,and about the metal top load,just put it on the Secondary coil………No need to fix

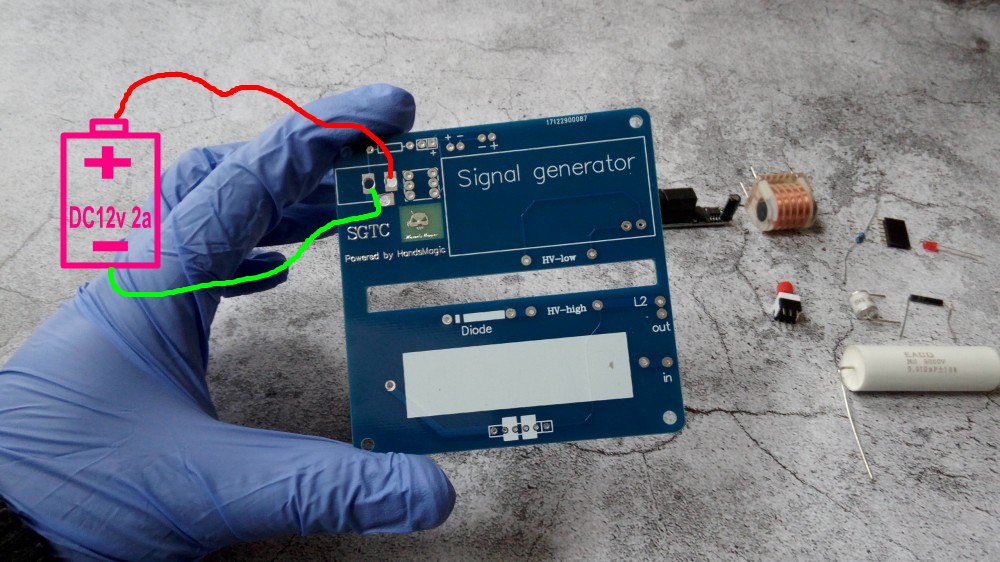

About the power suply:

you can use any DC12v power suply(make sure the out put current is 1A-2A)

For example:

if you don’t want to use the plug,you can solder two wire directly to the board,and connect them to your DC12v power

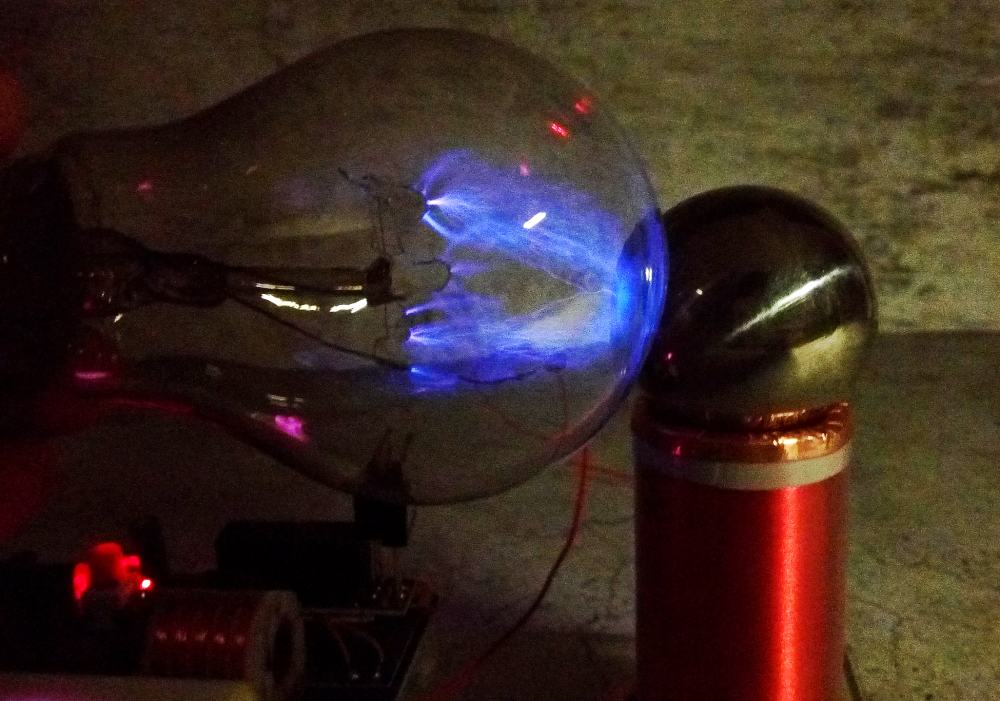

ok,all is done,12v dc power,you can use it now(plz use it in dark place,you can see the spark and arc)

find a Incandescent lamp

4 评论

Good evening, I just bought the tesla coil, I have a question: regarding the connection cable of the secondary coil (red color) where is it connected?

to L2

I cant stop the arc from the in line to the coil. I have tried every thing

you need Brush a layer of insulating paint